Swiftpack Automation IR Count-Heads

- X-25PSR Emitter-Receiver Pair

- X-25PSR Receiver Unit

- X-25PSR Emitter Unit

- X-35PSR Receiver Unit

- X-35PSR Emitter Unit

- X-25PSR Fitted to a Count-Head

The Swiftpack Automation CNTHD-25PSR and CNTHD-35PSR Count-Head Emitter-Receiver Pairs have been fitted to their Counting Machines for over a decade.

The Swiftpack Automation range of Counting Machines have included Single-Head Eight Track machines, through to Twin-Head Sixteen Track machines.

Each Track requires one Emitter-Receiver Pair.

The original Emitter-Receiver Pairs fitted to the Counting Machines suffered from a number of issues that effect the counting performance. These include inconsistant sensitivity and poor dust immunity.

They are also difficult to set-up and calibrate.

The new 'X' Type Emitter-Receiver Pairs supplied by Dicondi Limited overcome both these issues using a local CPU unit that continually monitors the counting performance.

Here are some of the key benefits:

- No calibration required - Uses a CPU auto-detect and adjust algorithm

- Easy Set-Up - No need to open up the head and make adjustments

- Low maintenance - The local CPU maintains the IR performance

- A minimum of 20dB electronic dust compensation (immunity)

- Detection Optimisation algorithm for different materials and sizes

- High accuracy automatic sensitivity control (16 bit)

- Fully EMC compliant with individual channel noise filtering

- Will work along side existing 'Original' units - no need to replace all

- Longer running periods without having to clean the glass

The 'X' type units come with a full Twelve Month Return-To-Base no quibble warranty. If they go wrong within the warranty period send them back and they will be replaced immediately with new.

The 'X' type units are also cheaper than the original units. Ask for a quote and see.

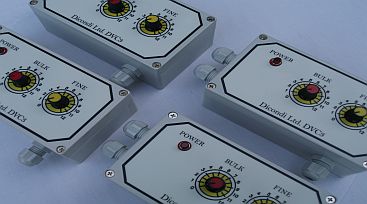

Vibratory Feeder Controllers

- DVC3 1 Channel Dual Variable Speed Control

- DVC3 With Bulk and Fine Variable Speeds

- DVC3s 1 Channel Single Variable Speed Control

- DVC3s With a Single Variable Speed

The DVC range of Vibratory Feeder Controllers are designed to offer a cost effective solution to controlling the speed (amplitude) of half wave Vibratory Feeders.

They are designed to connect direct to the mains supply, and supply controlled power to the Vibratory Feeder drive coil.

They can be used as a Stand-Alone Controller with full manual adjustment, or a 0-10V remote demand controlled solution, for use with Automatic Linear-Weighers, Bag-Feeders, PLC controller Cross-feeders etc.

The control input signals operate from 15Vdc to 26Vdc. They can be connected to operate from both NPN (Low Switched) and PNP (High Switched) signals.

The control inputs are designed with Linear-Weighers requiring Bulk (Fast) and Fine (Slow) feed speeds in mind.

There are a number of different models available, including Single, Dual and Three channels, Single speed and Dual speed amplitude control, and different power variants.

They are also available in various ingress integrity levels from IP55 upwards.

The DVC range can also be offered as a fully customised design to fit your exact requirements.

They are extremely competitively priced, so please contact us for a quotation.

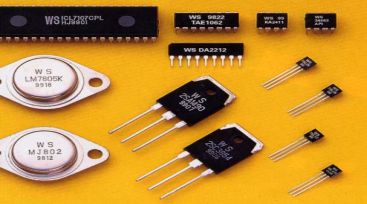

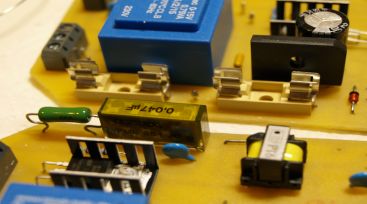

Custom Control Systems

The design and manufacture of custom control systems is a part of the Dicondi Ltd business that supports customers who want something unique for their application.

Be it a one off design, or a small volume production run, we are able to support the customers needs.

This service allows the customer to have the design integrated into their machine, or have a 'bolt-on' box that is easy to fit and maintain.

The options are endless. What-ever the requirements they can be accomodated. What-ever the application there is a solution that will make it work.

If you want a set of controls for a new machine, replace the controls on a old machine, or you have a novel idea that requires something special, we can help.

It's not just machine controls, we have supplied custom designs for dynamic art, workshop distribution and control, agriculture and transport.

Talk to us about your requirements, and we will find the solution.

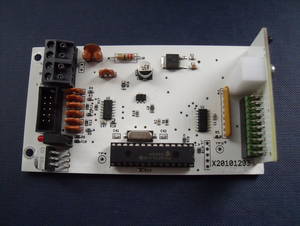

Controller Front Panel Overlay (Label) Custom Designs

We design custom overlays (labels) to carry your Logo and company name (Badge Engineered) to put your company mark on refurbished machinery.

When refurbishing and reselling a machine, why keep the original manufacturers name on it, and promote their business. Put your mark on all the machinery you sell by changing the the name and logo on the controller overlay (label) to yours.

The examples in the photographs originally carried another companies name and logo, now they are fitted with brand-new overlays (labels) carrying the name and logo of the company who refurbished the machine.

The name of the company who put in all the hard work and time refurbishing the machine is now displayed for all to see, promoting their business and not others.